Analyzes for metals

Metal analysis

Metal analysis to the highest standard is our claim. Our analyzes are carried out in laboratories that are tested and confirmed at regular intervals according to the ISO standard DINEN ISO 9001. By working with our analytics partner, we have access to the full range of state-of-the-art equipment and a variety of well-trained chemists. The metal analysis takes 5-7 business days. Even the most demanding analyzes are in good hands with us.

IMPORTANT:

Only if ALL elements from lithium, number 3 in the periodic table, to uranium, number 92 in the periodic table, are checked, a purity can be determined in the elimination process. We often have analyzes in which the content of only 30 elements or less is recorded. It is not possible to determine the quality in this way. Should you commission your analysis elsewhere, please make sure that all elements are checked. You are welcome to print out the PDF below as a sample.

sampling

An analysis begins with the sampling. If you only want to know the result of a metal sample, so is it enoughwhen they send a sample to us that is being analyzed.

However, if you want to know the quality of your entire lot, it is essential that either all of the goods come to us or we come to the goods to take samples at random. We will open 4-6 goods containers at random and take samples. For a qualified analysis we need 5 grams of goods. The entire process is documented with photos and recorded on the basis of records. After removal, all containers are properly closed again with ISE security seals and also recorded.

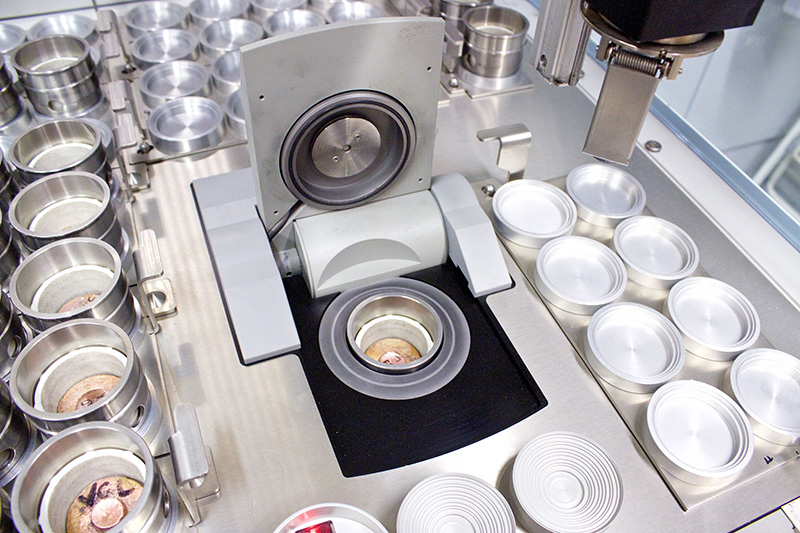

Example of a sampling:

If desired, the analysis will provide you with a sample collection protocol. This includes accurate collection procedure in written form supplemented with photos. This process is important in order to prove to a prospective customer that the entire product is a consistent quality.

Example of photo documentation:

Analysis

An analysis begins with the sample preparation. In this step, the samples are mechanically brought into a suitable shape.

The ICP-MS and ICP-OES analysis requires digestion of the metal. As a rule, this is the acid digestion of metals (HNO3 / HCI, H2SO4 / HCI, H2O2 / HCI).

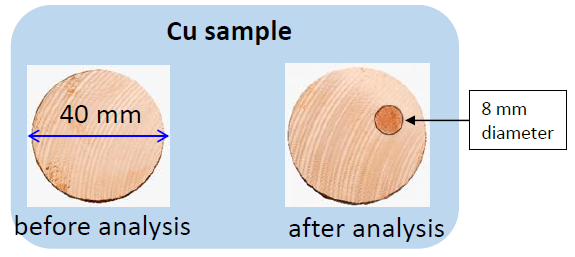

Example of an analysis for copper powder with quality, shape and size determination.

Only in the third step, the actual analysis activity takes place. Here the following devices are used:

GD MS

Glow Discharge - mass spectrometry (Solid-MS)

GD-MS Glow Discharge - Mass spectrometry. Individual elements are accelerated with a very strong magnet. The acceleration curve separates and identifies individual elements and isotopes.

This process is carried out directly on the solid body without chemical decomposition:

- Analysis of pure metals

- Analysis of metal alloys

- Analysis of non-conductive materials

- Analysis of powders

- Analysis of wires

- Analysis of (almost) all metal forms

A GD Plus Glow Discharge Mass Spectrometer (GD-MS) from Thermo Scientific is used

ICP-MS

Mass Spectrometry with inductively coupled plasma.

This procedure is used in:

- trace analysis

- quantitative measurement of up to 60 elements simultaneously

- Semiquantitative measurement

- Total spectrum

An ICP-MS, PlasmaQuant MS from Analytik Jena is used

ICP OES

Emission spectrometry with inductively coupled plasma.

This procedure is used in:

- Analysis of metals

- Analysis of ceramics

- Analysis of organic samples

- Analysis of water

- Analysis of solutions

- Analysis of minerals

A Spectro Arcos from Spectro / Ametek is used

Analysis example as PDF

We analyze 76 elements in the GD-MS process and can determine the purity up to 7N (99,99999%) metal in the following exclusion process. Only when all elements are verified can the final purity be determined in an exclusion process.

In the following example you can see which elements we are testing:

Prices for ISE services

In the following PDF document you will find the ISE prices for analyzes, evaluations, programs and sales of metals.

This price list covers most of the customer's wishes. We are constantly confronted with something new. So please do not hesitate to contact us. We find solutions.

More impressions from our laboratory

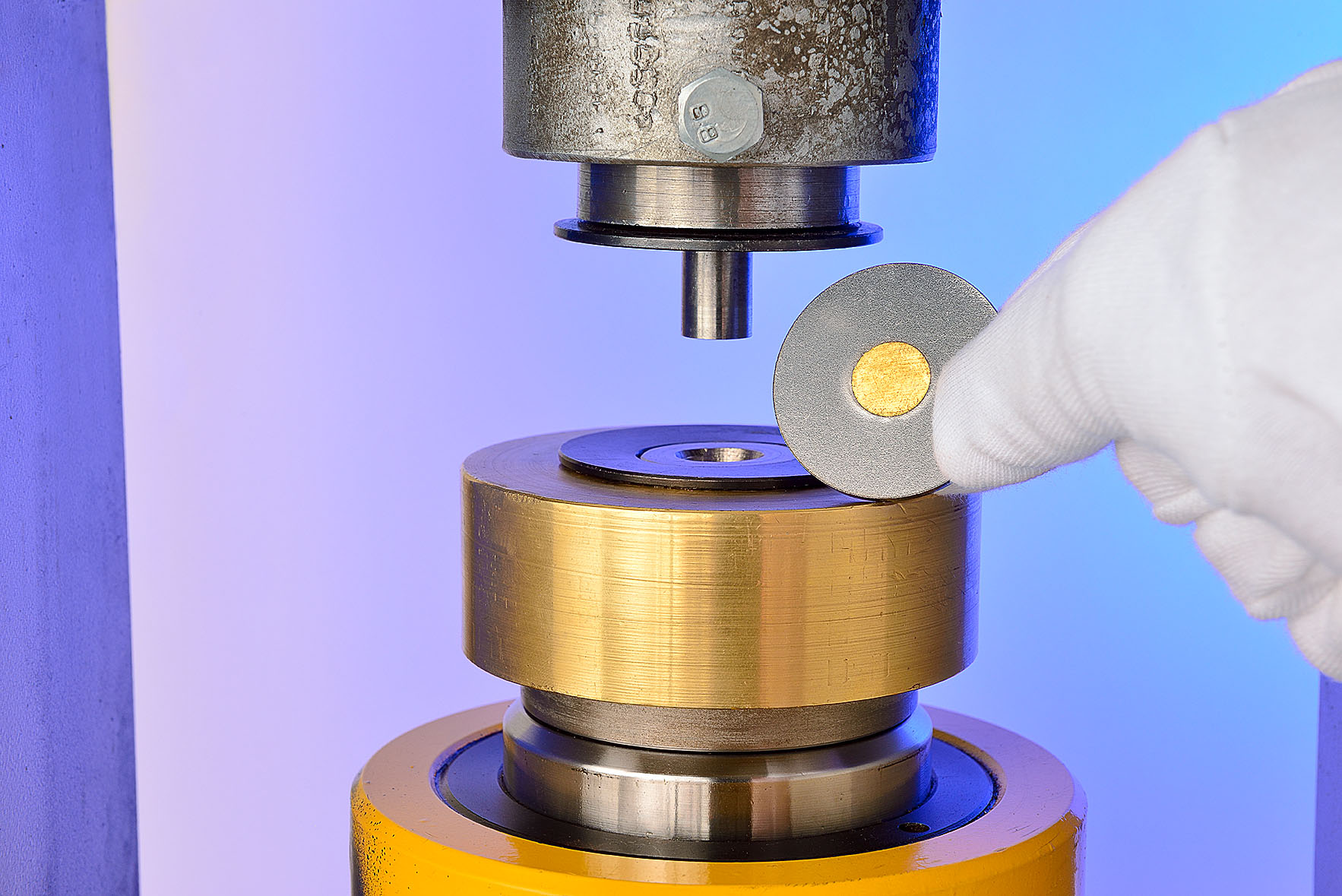

A copper powder sample was pressed into a steel ring in preparation for GD-MS analysis

Copper sample before and after the GD-MS analysis

100 tons press - The production of pellets for the preparation of solid or powdery substances is still daily practice in analysis. We use hydraulic presses of various sizes up to 5 ton presses for the production of high-quality pellets from 40 mm to 100 mm in diameter.

ISE seals, security glues and other non-laminated security labels secure your goods and keep your analysis up-to-date.

In particle analysis, a digital image of a sample is analyzed according to the number, size and size distribution of the particles. Learn more…

The applications of nanoparticles are as diverse as their shape and properties. Technically, the "dwarfs" can be produced, for example, by grinding larger particles. Planetary Ball Mills reach the energy inputs required for this nano-milling.

If you have questions about this topic, please contact: [email protected]