Tin, Sn, atomic number 50

Tin price, occurrence, extraction and use

Tin is a chemical element with the element symbol Sn (Latin stannum) and the atomic number 50. In the periodic table it is in the 5. Period and in the 4. Main group, or 14. IUPAC group or carbon group. The silvery white and very soft heavy metal can be carved with your fingernail. Tin has a very low melting point for metals. Its main use has been in the manufacture of crockery, from pewterers within urban craft guilds to 19. Century were manufactured as widespread utility and ornaments as components of the bourgeois households. Modern use takes place in the field of electric brazing as well as in the tinning of food-grade preserves or in medicine. Historically, man has first used tin as an admixture to copper as an alloying agent for making the bronze.

etymologie

The word tin (ahd., Mhd. Zin) is perhaps related to ahd. Zein "rod", "chopsticks", "branch" (see Zain). The Duden points out in this context that the metal was formerly poured in rod form. Another explanation assumes that the main tin ore cassiterite (Zinnstein) also occurs in the form of needles or "sticks".

History

The metallurgical processing of tin started somewhat later than that of copper. While the smelting of copper for the Vinča culture on 5400-4800 v. Chr. It was dated in the Balkans in the 3rd century BC in the area of today's Iran and Turkey between 5200 and 5000 v. Chr. Chr. The oldest dated tin-bronze tin-stannite alloy was found in the Pločnik archaeological site in the territory of present-day Serbia at about 4650 BC. Dated. In the southern Turkish Taurus Mountains, where tin ore could also have been mined, the Kestel Mine and the Göltepe processing plant were discovered and recorded at about 3000 BC. Dated. Whether this was the source of the great consumption of tin in the East Asian market remains unanswered for the time being. Pewter bronzes, gold and copper were first used as jewelry only for their color. The Vinča culture's first metalsmiths presumably chose tin-containing minerals because of their black-green color, which was similar to manganese-rich copper ores. The metal forges of the tin bronzes were aware of the specific properties of the new metal, which can be deduced from the techniques used in processing the tin rich ores.

At the end of the 3. Millennium BC Chr. (Botanical dates on 2021 and 2016 v. Chr.) Elves resident in the Elbe valley elite year by year in the summer months Zinngraupen at the Red Weisseritz near Schellerhau. The workers lived in simple tabernacles during the season, the tin was made in the solid settlements in the Elbe Valley, which thereby prospered and came to wealth and prestige. At that time, the Erzgebirge developed into a central supplier for the whole of Europe. Tin was essential for bronze production. The traces of mining discovered in Schellerhau by the research project Archeo Montan are currently the oldest in Europe.

Egypt, Near Eastern and Asian civilizations

By the alloy bronze, whose components are copper and tin, tin became more important (Bronze Age). For Egypt, the use of tin confirmed by finds of small bronze statuettes from the time of the pyramids (4 Dynasty, to 2500 BC). Also in an Egyptian tomb from the 18. Dynasty (around 1500 BC) found tin objects. In India, the bronze production was already around 3000 v. Known. Since the 2. Millennium BC In the 1st century BC, tin was mined in Central Asia on the route of the later Silk Road to a greater extent in mines. From about 1800 v. Tin is known in China (Shang Dynasty). A textbook on the arts of that time, the Kaogong ji (Zhou Dynasty, from 1122 BC), describes in detail the mixing ratios of copper and tin, depending on the type of sacred vessels, gongs, swords and arrowheads, axes or Agricultural equipment to be used bronze were different. Already earlier it should have been known in the actual Asian deposits in Yunnan and on the peninsula Malacca. In the valley of the Euphrates since 2000 v. Chr. Chr. Bronze devices and their production to a significant cultural factor; the technique was then further developed by Greeks and Romans.

Early trade: Western and Central Asia, Phoenician

The spread of tin trade also confirms its early and far-reaching exploitation. It was first brought from Central Asia with caravans in the areas of today's Near and Middle East. There they got the tin ore from the 3. Millennium BC From the deposits of the ancient empire Elam east of the Tigris and from the mountains of Khorasan on the Persian border with Turkmenistan and Afghanistan. From there it seems to have passed it on to the land of the pharaohs. The Bible turns tin into 4. Book of Moses first mentioned (Numbers 31,22 EU).

The Phoenicians probably had connections by sea with the tin-rich Indian islands of Malacca and Bangka, without giving precise details. Later the Phoenicians transported the tin ore with their ships along the Spanish and French coastal areas to the islands in the North Sea. On these trips they discovered areas rich in tin on the so-called Tin Islands, which may include the Isle of Wight, and in the mountains of Cornwall, where they mined the ore and exported it to other countries. To a lesser extent, tin ore mining began to a commercial extent in France (including at Cap de l'Etain), in Spain (Galicia) and in Etruria (Cento Camerelle near Campiglia Marittima).

Greeks and Romans

In the epics of Homer and Hesiod, tin deposits appear as ornamental ornamentation on chariots and shields of Agamemnon and Heracles; For Achilles, tin (probably "tinned") greaves are described. Tin is first mentioned by Plautus as dishes for food. As a commodity for crockery, it was probably unknown to the Greeks. The tin, which the Greeks used for bronze casting, came, according to Herodotus, from the Kassites, whose geographical position was unknown to them. These islands are also mentioned and described by Strabon, who locates them far north of Spain, near Britain.

The Roman writer Pliny called tin in its natural history plumbum album ("white lead"); Lead, however, was plumbum nigrum ("black lead"). He also describes the tinning of copper coins and reports on tin mirrors and ampoules and describes that lead-acid tubes were soldered with tin alloy. The high demand for tin assigned to Jupiter in alchemy is even cited as a reason for the Roman occupation of Britain. In the southwestern region of Cornwall was by 2100 v.. Promoted to 1998 tin ore, in antiquity an important tin supplier of the Mediterranean and into the late 19. Century the largest in the world. In Latin tin stannum is called, hence the chemical symbol (Sn) also touches.

Middle Ages

During the migration of peoples the miner mining of tin ores was completely paralyzed. Only a few cult objects were still manufactured. At the Council of Reims (813), in addition to gold and silver, only tin is expressly permitted for the manufacture of such items. The findings of the tombs of Capetiennes confirm this insofar as at the time of the First Crusades it was customary to add priests with pewter goblets and bishops as well as abbots with tin crumbs.

The custom of wearing small images of tin alloy, so-called pilgrim's mark, on the chest probably also dates back to the time of the Crusades. Depending on the region, these were in central and southern France St. Denis and St. Nicolas, in England St. Thomas of Canterbury. The religious coins and ampoules, small bells and whistles brought home by the Palestinian pilgrimage were of tin. They had to be thrown into the rivers and lakes after the pilgrimage was acknowledged to avert possible misuse.

Beginning with 1100, the population in Europe gradually began to replace the traditional dinnerware made of clay and wood with that from the more stable tin. Around 1200 began in the larger cities, the craftsmanship of tin in tin foundries. At that time, the Venetians maintained trade relations with the tin-rich Indian islands of Malacca and Bangka.

Long after bronze had been supplanted by iron (Iron Age), Tin attained middle of the 19. From the beginning of the 20th century, the industrial production of tinplate once again made a great deal of importance.

Production and occurrence

Zinnerzgewinnung in Altenberg 1976

Octahedron-shaped cassiterite crystals, approx. 3 cm edge length from Sichuan, China

Primary tin occurrences include greisen, hydrothermal gangrene and, more rarely, skarn and volcanic exhalation (VHMS) deposits. As the most economically important tin mineral, cassiterite SnO2, also called tin stone, is a very stable heavy mineral, much of the tin production also comes from secondary soap deposits. In some primary deposits, the sulfide mineral stannite Cu2FeSnS4 is also important for tin production. On primary tin deposits, the element is often associated with arsenic, tungsten, bismuth, silver, zinc, copper, and lithium.

For the extraction of tin, the ore is first crushed and then enriched by various methods (slurrying, electrical / magnetic divorce). After reduction with carbon, the tin is heated just above its melting temperature so that it can flow away without higher melting impurities. Today, most of them are recovered through recycling and here through electrolysis.

It is present in the continental crust at a level of about 2,3 ppm.

The current reserves for tin are given as 4,7 million tons, with an annual production of 289.000 tons in the year 2015. At over 80%, production currently comes from soap deposits (secondary deposits) on rivers and in the coastal area, primarily from one region, starting in central China via Thailand to Indonesia. The world's largest tin deposits were discovered at 1876 in the Kinta Valley (Malaysia). There, about 2 million tons have been mined to date. The material in the alluvial deposits has a metal content of about 5%. Only after several steps to concentrate to about 75% is a melting process used.

In Germany, larger resources are available in the Erzgebirge, where the metal from the 13. Century until 1990 was won. Examples are the geriatric deposit Altenberg and the skarn deposit Pöhla. Various companies are currently exploring for tin in the Erzgebirge. In August 2012 published first investigation results for the places Geyer and Gottesberg, a district of Muldenhammer, let occurrences in the amount of approximately 160.000 tons tin for both places altogether presumably. In principle, these figures also confirm information as estimated by prospecting conducted in GDR times. According to Deutsche Rohstoff AG, it is the world's largest untapped tin deposit. Since on the one hand the ore content with 0,27 percent for Gottesberg and 0,37 percent for Geyer is relatively small, on the other hand, the ore is relatively difficult to solve from the rock, it is unclear whether the mining would be economically worthwhile. Should that happen, zinc, copper and indium would also be a by-product.

The most important source for tin is China, followed by Indonesia and Myanmar. In Europe, 2009 Portugal was the largest producer, where it is promoted as a by-product of the VHMS deposit Neves Corvo.

Kassiterit was classified by the US Securities and Exchange Commission SEC as a so-called "conflict mineral", whose use for companies is reportable to the SEC. The reason given for this are the production sites in eastern Congo, which are controlled by rebels and are thus suspected of co-financing armed conflicts.

The states with the largest tin extraction worldwide

(2009 and 2015) and Estimated Reserves (2017):

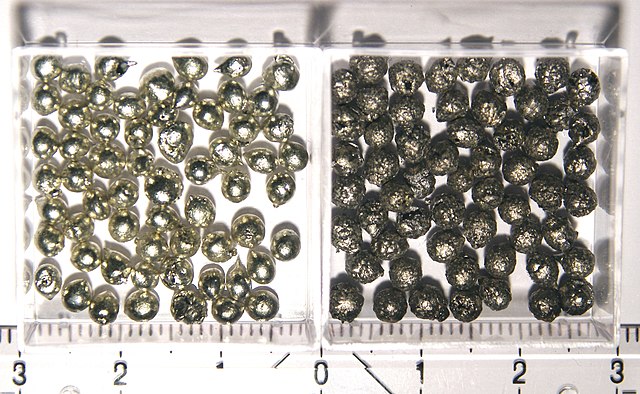

faced β- (left) and α-tin (right)

Features

Tin can adopt three modifications with different crystal structure and density:

- α-Tin (cubic diamond lattice, 5,75 g / cm3) is stable below 13,2 ° C and has a bandgap of EG = 0,1 eV. Depending on the interpretation, it is classified as a semi-metal or semiconductor. His color is gray.

- β-tin (distorted octahedral, 7,31 g / cm3) to 162 ° C, surface silver-white.

- γ-tin (rhombic lattice, 6,54 g / cm3) above 162 ° C or under high pressure.

In addition, a two-dimensional modification called Stanen can be synthesized.

Natural tin consists of ten different stable isotopes; this is the largest number among all elements. In addition, 28 radioactive isotopes are still known.

The recrystallization of β-tin to α-tin at low temperatures manifests itself as the so-called Zinnpest.

When bending the relatively soft tin, for example, of tin rods, a characteristic noise, the Zinngeschrei (also tin cry) occurs. It is caused by the friction of the β-crystallites together. However, the noise only occurs with pure tin. Already low alloyed tin does not show this property; z. B. prevent small admixtures of lead or antimony the Zinngeschrei. The β-tin has a flattened tetrahedron as a spatial cell structure from which two additional compounds form.

Due to the oxide layer with which tin is coated, it is very stable. However, it is decomposed by concentrated acids and bases with evolution of hydrogen gas. However, tin (IV) oxide is similarly inert as titanium (IV) oxide. Tin is reduced by less noble metals (eg zinc); At the same time, elemental tin separates out spongy or adheres to the zinc.

isotope

Tin has a total of ten naturally occurring isotopes. These are 112Sn, 114Sn, 115Sn, 116Sn, 117Sn, 118Sn, 119Sn, 120Sn, 122Sn and 124Sn. 120Sn is the most abundant isotope with 32,4% content of natural tin. Of the unstable isotopes, 126Sn is the most long-lived with a half-life of 230.000 years. All other isotopes have a half-life of only a maximum of 129 days, but 121Sn has a core isomer with 44 years of half-life. The most commonly used tracers are the isotopes 113Sn, 121Sn, 123Sn and 125Sn. Tin is the only element with three stable isotopes of odd mass and, with ten stable isotopes, the most stable isotopes of all elements.

| iso- top |

half-life time |

decay energy (MeV) |

Spin / parity |

Decay (s) (%) |

||

|---|---|---|---|---|---|---|

| 100Sn | (1,16 ± 0,2) s | 7,27 (εβ+), 5,70 (εp) | 0+ | εβ+ ≈ 100, εp <17 | ||

| 101Sn | 3 s | 8,8 (εβ+), 7,5 (εp) | εβ+ ≈ 100, εp =? | |||

| 102Sn | 4,5 s | 5,4 | 0+ | εβ+ | ||

| 103Sn | 7 s | 7,7 | εβ+ | |||

| 104Sn | 20,8 s | 4,52 | 0+ | εβ+ | ||

| 105Sn | 31 s | 6,25 (εβ+), 3,45 (β+p) | εβ+ ≈ 100, β+p =? | |||

| 106Sn | 115 s | 3,18 | 0+ | εβ+ | ||

| 107Sn | 2,90 min | 5,01 | (5 / 2 +) | εβ+ | ||

| 108Sn | 10,30 min | 2,092 | 0+ | εβ+ | ||

| 109Sn | 18,0 min | 3,850 | 5 / 2 (+) | εβ+ | ||

| 110Sn | 4,11 hours | 0,638 | 0+ | ε | ||

| 111Sn | 35,3 min | 2,445 | 7 / 2 + | εβ+ | ||

| 112Sn | stable 2e | 0+ | ||||

| 113m1Sn | 21,4 min | 0,077 (IT), 1,113 (εβ+) | 7 / 2 + | IT = 91,1, εβ+ = 8,9 | ||

| 113Sn | 115,09 d | 1,036 | 1 / 2 + | εβ+ | ||

| 114m1Sn | 3,26 μs | 0,613 | 7 / 2 + | IT | ||

| 114m2Sn | 159 μs | 0,713 | 11 / 2 + | IT | ||

| 114Sn | stable SF | 0+ | ||||

| 115Sn | stable SF | 1 / 2 + | ||||

| 116Sn | stable SF | 0+ | ||||

| 117m1Sn | 13,60 d | 0,315 | 11 / 2- | IT | ||

| 117Sn | stable | 1 / 2 + | ||||

| 118Sn | stable SF | 0+ | ||||

| 119m1Sn | 293,1 d | 0,090 | 11 / 2- | IT | ||

| 119Sn | stable SF | 1 / 2 + | ||||

| 120Sn | stable SF | 0+ | ||||

| 121m1Sn | 44 to | 0,006 (IT), 0,394 (β-) | 11 / 2- | IT = 77,6, β- = 22,4 | ||

| 121Sn | 27,06 hours | 0,388 | 3 / 2 + | β- | ||

| 122Sn | stable 2b | 0+ | ||||

| 123m1Sn | 40,06 min | 1,429 | 3 / 2 + | β- | ||

| 123Sn | 129,2 d | 1,404 | 11 / 2- | β- | ||

| 124m1Sn | 45 μs | 2,657 | 10+ | IT | ||

| 124Sn | stable 2b | 0+ | ||||

| 125m1Sn | 9,52 min | 2,364 | 3 / 2 + | β- | ||

| 125Sn | 9,64 d | 2,364 | 11 / 2- | β- | ||

| 126Sn | 1 · 105 a | 0,380 | 0+ | β- | ||

| 127m1Sn | 4,13 min | 3,206 | (3 / 2 +) | β- | ||

| 127Sn | 2,10 hours | 3,201 | (11 / 2-) | β- | ||

| 128m1Sn | 6,5 s | 2,092 | (7-) | IT | ||

| 128Sn | 59,07 min | 1,274 | 0+ | β- | ||

| 129m1Sn | 6,9 min | 4,035 (β-), 0,035 (IT) | (11 / 2-) | β- ≈ 100, IT ≈ 2 · 10−4 | ||

| 129Sn | 2,23 min | 4,000 | (3 / 2 +) | β- | ||

| 130m1Sn | 1,7 min | 4,097 | (7-) | β- | ||

| 130Sn | 3,72 min | 2,150 | 0+ | β- | ||

| 131m1Sn | 58,4 s | 4,880 (β-), 0,242 (IT) | (11 / 2-) | β- ≈ 100, IT <0,009 | ||

| 131Sn | 56,0 s | 4,638 | (3 / 2 +) | β- | ||

| 132Sn | 39,7 s | 3,30 | 0+ | β- | ||

| 133Sn | 1,45 s | 7,99 (β-), 0,69 (β-n) | (7 / 2-) | β- ≈ 100, β-n = 0,08 | ||

| 134Sn | 1,12 s | 6,8 (β-), 3,7 (β-n) | 0+ | β- ≈ 100, β-n = 17 |

proof

As a qualitative detection reaction for tin salts, the illuminated sample is carried out: The solution is mixed with about 20% hydrochloric acid and zinc powder, whereby nascent hydrogen is released. The nascent, atomic hydrogen reduces part of the tin to stannane SnH4. Into this solution is immersed a test tube filled with cold water and potassium permanganate solution; The potassium permanganate serves only as a contrast agent. This test tube is held in the dark in the non-luminous Bunsen burner flame. In the presence of tin immediately produces a typical blue fluorescence, caused by SnH4.

The polarography is suitable for the quantitative determination of tin. In 1 M sulfuric acid, tin (II) gives a step at -0,46 V (vs. calomel electrode, reduction to element). Stannate (II) can be oxidized to stannate (IV) in 1 M caustic soda (-0,73 V) or reduced to the element (-1,22 V). In the ultra-trace range, the graphite tube and hydride techniques of atomic spectroscopy are suitable. The graphite tube AAS achieves detection limits of 0,2 μg / l. In hydride technology, the tin compounds of the sample solution are transferred into the quartz cuvette using sodium borohydride as gaseous stannane. There, the stannane decomposes at about 1000 ° C in the elements, the atomic tin vapor specifically absorbs the Sn lines of a tin hollow cathode lamp. Here, 0,5 μg / l has been reported as detection limit.

Further qualitative detection reagents are diacetyldioxime, kakothelin, morin and 4-methylbenzene-1,2-dithiol. Tin can also be detected microanalytically via the formation of gold purple.

Biological effect

Metallic tin is nontoxic even in large quantities. The toxicity of simple tin compounds and salts is low. Some organic tin compounds, on the other hand, are highly toxic. The trialkyltin compounds (especially TBT, tributyltin) and triphenyltin have been used in marine paints for several decades to kill the microorganisms and shellfish that attach to the hulls. As a result, high concentrations of TBT in the seawater near major port cities have affected the population of marine life to this day. The toxic effect is due to the denaturation of some proteins through the interaction with sulfur from amino acids such as cysteine.

Usage

Traditional use and traditional professions

Ingots made of alloyed tin (97,5% Sn)

Small smelting furnace

Production of pewter jugs, Bayrischform-Kandl

Pure tinplate has been used extensively for centuries as an organ metal in the field of vision for centuries. These retain their silvery color over many decades. However, the soft metal is usually used in an alloy with lead, the so-called organ metal, and has very good vibration-damping properties for the development of sound. Too low temperatures are detrimental to organ pipes because of their conversion into α-tin; see Zinnpest. Many household items, pewter (utensils), tubes, cans and pewter figurines were once made entirely of pewter, all of which conformed to the simpler processing technology of the time. In the meantime, however, the relatively precious material has mostly been replaced by cheaper alternatives. Decorative and costume jewelery will continue to be made of tin alloys, pewter or Britannia metal.

Since the Middle Ages the pewterer was a special craft profession, which has survived to this day, albeit to a very small extent. He is now legally in the job title metal and bell founder / -in merged. The task of the Zinnputzers was the cleaning of mainly oxidized, manufactured from tin objects with a cold water extract of the field horsetail, which was popularly therefore called horsetail. It was a relatively minor traveling business and was practiced in the homes of middle-class or large-scale households.

Today's use

The annual world consumption of tin is around 300.000 t. Around 35% of this is used for solders, around 30% for tinplate and around 30% for chemicals and pigments. By switching from tin-lead solders to lead-free solders with tin contents> 95%, the annual demand will increase by around 10%. World market prices have increased continuously in recent years. In 2003, the LME (London Metal Exchange) paid around 5000 US dollars per ton, but in May 2008 it was already more than 24.000 US dollars per ton. The ten largest tin consumers (2003) worldwide are the USA, Japan, Germany, the rest of Europe, Korea, the rest of Asia, Taiwan, Great Britain and France in first place after China.

The global financial crisis as of 2007 and weak economic growth in emerging and developing countries put the price under pressure. In August 2015, the price per ton dropped short to below 14.000 US dollars. In October 2015, the price had recovered slightly to around 16.000 dollars again. Due to the strong US dollar, the low price is only partially available in many consumer countries. 2011's worldwide production was around 253.000 tonnes, of which 110.000 tons were produced in China alone; another 51.000 tons came from Indonesia. Due to the relatively low revenue from the export of tin compared to oil or natural gas, for example, it does not play any special economic role in the producing countries.

Tin is widely used as alloying element, alloyed with copper to bronze or other materials. Nordic gold, the alloy of the gold Euro coins, includes 1% tin. Algerian metal contains 94,5% tin.

As a component of low melting point metal alloys, tin is irreplaceable. Soft solder (so-called solder) for connecting electronic components (for example on printed circuit boards) is alloyed with lead (a typical mixture is about 63% Sn and 37% Pb) and other metals in a smaller proportion. The mixture melts at about 183 ° C. Since July 2006, however, lead-based soldering tin must no longer be used in electronic devices (see RoHS); They now use lead-free tin alloys with copper and silver, z. Eg Sn95.5Ag3.8Cu0.7 (melting temperature approx. 220 ° C).

Since one does not trust these alloys (Zinnpest and "Tin whiskers"), is in the production of electronic assemblies for medical technology, security technology, measuring instruments, air and. Space and military / police use continue to allow the use of leaded solders. On the contrary, the use of lead-free solder in these sensitive areas is prohibited despite RoHS.

High purity tin single crystals are also suitable for the production of electronic components.

In float glass production, the viscous glass mass floats until it solidifies on a mirror-smooth liquid tin melt.

Tin compounds are added to the plastic PVC as stabilizers. Tributyltin serves as a so-called anti-fouling additive in paints for ships and prevents the fouling of the hull, but it is now controversial and largely prohibited.

In the form of a transparent tin oxide-indium oxide compound, it is an electrical conductor in display devices such as LC displays. The pure, white, not very hard tin dioxide has a high refraction of light and is used in the optical range and as a mild polishing agent. In dentistry, tin is also used as a component of amalgams for tooth filling. The very toxic organic tin compounds are used as fungicides or disinfectants.

Tin is used instead of lead also for lead pouring. Stannum metallicum ("metallic tin") is also used in the production of homeopathic medicines as well as tapeworm antidote.

Under the name Argentin, tin powder was formerly used to make fake silver paper and fake silver foil.

Tinplate is tinned sheet iron, it is used for example for cans or bakeware. Tin, the English word for tin, is at the same time an English word for tin or tin can.

Rolled to a thin film called it also Stanniol, which is used for example for tinsel. However, tin is in the 20. Century has been supplanted by the much cheaper aluminum. Tin is also used in some paint tubes and wine bottle locks.

Tin is used in EUV lithography for the production of integrated circuits ("chips") - as a necessary component in the generation of EUV radiation by tin-plasma.

Connections

Tin compounds occur in the oxidation states + II and + IV. Tin (IV) compounds are more stable, since tin is an element of the IV. Main group and also the effect of the inert electron pair is not as pronounced as in the heavier elements of this group, z. B. the lead. Tin (II) compounds can therefore be easily converted into tin (IV) compounds. Many tin compounds are inorganic in nature, but it is also a number of organotin compounds (tin organyls) known.

Oxides and hydroxides

- Tin (II) oxide SnO

- Tin (II, IV) oxide Sn2O3

- Tin (IV) oxide SnO2

- Tin (II) hydroxide Sn (OH) 2

- Tin (IV) hydroxide Sn (OH) 4, CAS number: 12054-72-7

halides

- Tin (II) fluoride SnF2

- Tin (II) chloride SnCl2

- Tin (IV) chloride SnCl4

- Tin (IV) bromide SnBr4

- Tin (II) iodide SnI2

- Tin (IV) iodide SnI4

Sugar and salt

- Tin (II) sulfate SnSO4

- Tin (IV) sulfate Sn (SO4) 2

- Tin (II) nitrate Sn (NO3) 2

- Tin (IV) nitrate Sn (NO3) 4

- Tin (II) oxalate Sn (COO) 2

- Tin (II) pyrophosphate Sn2P2O7

- Zinc Hydroxystannate ZnSnO3 · 3 H2O, CAS Number: 12027-96-2

chalcogenides

- Tin (II) sulfide SnS

- Tin (IV) sulfide SnS2

- Tin (II) selenide SnSe

Organic tin compounds

- Dibutyltin dilaurate (DBTDL) C32H64O4Sn

- Dibutyltin oxide (DBTO) (H9C4) 2SnO

- Dibutyltin diacetate C12H24O4Sn, CAS Number: 1067-33-0

- Diphenyltin dichloride C12H10Cl2Sn

- Tributyltin hydride C12H28Sn

- Tributyltin chloride (TBTCL) (C4H9) 3SnCl

- Tributyltin fluoride (TBTF) C12H27FSn, CAS Number: 1983-10-4

- Tributyltin sulfide (TBTS) C24H54SSn2, CAS Number: 4808-30-4

- Tributyltin oxide (TBTO) C24H54OSn2

- Triphenyltin hydride C18H16Sn

- Triphenyltin hydroxide C18H16OSn

- Triphenyltin chloride C18H15ClSn

- Tetramethyltin C4H12Sn

- Tetraethyltin C8H20Sn

- Tetrabutyltin C16H36Sn

- Tetraphenyltin (H5C6) 4Sn

Further connections

- Stannane SnH4

- Sodium stannate Na2SnO3

- Potassium stannate K2SnO3, CAS number: 12142-33-5

- Tin difluoroborate Sn (BF4) 2, CAS Number: 13814-97-6

- Zinn(II)-2-ethylhexanoat Sn(OOCCH(C2H5)C4H9)2

- Tin (II) oleate Sn (C17H34COO), CAS number: 1912-84-1

- Tin telluride SnTe

- Indium-tin oxide, a mixed oxide usually composed of 90% indium (III) oxide (In2O3) and 10% tin (IV) oxide (SnO2)

Tin prices

Tin price -> prices for base metals

Sources:

Wikipedia, ECHA, Roskill, Strabo, LME

Image sources: Wikipedia