Whenever a hard disk or a DVD player lands in the garbage in Germany, rare earth metals are lost. For the Öko-Institut this waste is unacceptable. It demands a recycling system for the expensive raw material.

A small hard drive from Toshiba: Rare earth is often in the high-performance magnets of the small engines. In the scrapping they go so far irretrievably lost.

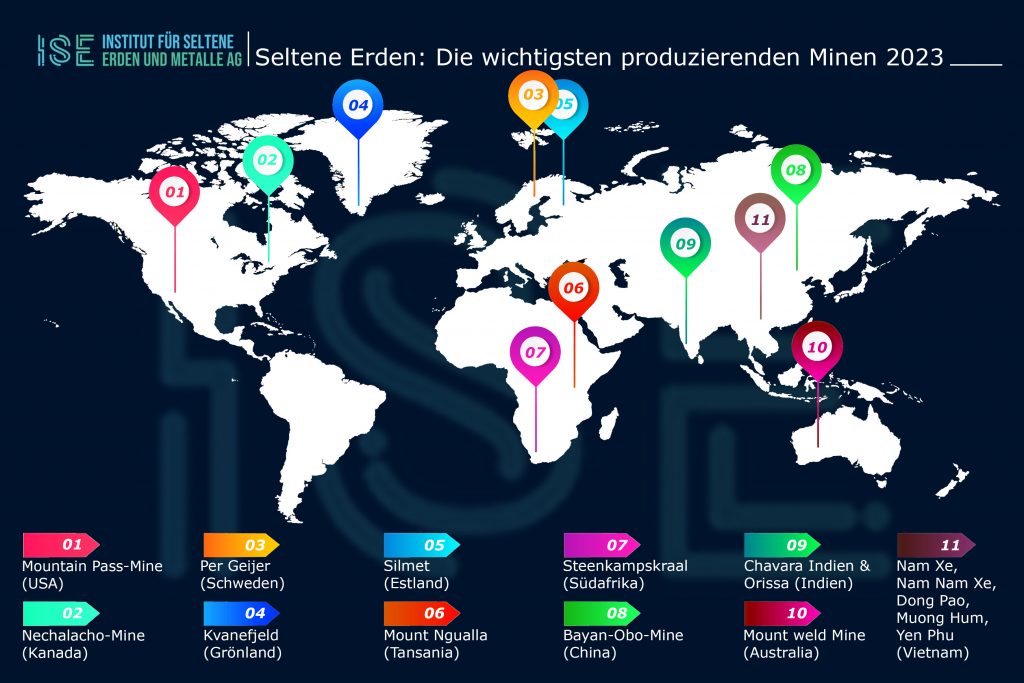

The term rare earths is misleading, but has long been naturalized. Actually, it's about oxides - which were formerly called earths - that naturally occur in a group of 17 elements in the Earth's crust. These include, for example, cerium, yttrium and neodymium. Rare earths are mined, especially in China, which has the world's largest deposit in Mongolia.

Today comes the rare earths in many key technologies for use. They appear in polishes, special glasses, in fluorescent lamps, tube and plasma screens. They are used in the manufacture of permanent magnets, which are used in modern and highly efficient electric motors. The Öko-Institut, a private environmental research institute based in Freiburg, has now investigated the recycling potential for rare earths in a study.

For the study, the Öko-Institut had interviewed several hundred industrial companies in Baden-Württemberg on behalf of the Baden-Württemberg Ministry of the Environment. The conclusion: "The potential for recovering the rare earths is not lifted and urgently needs to be tapped." European companies have made 2012 up to two million electric motors with permanent magnets for industrial applications, according to the study.

Rare earths are in high-performance magnets of hard disk motors

About half of these permanent magnets, which contained about 30 percent of rare earths, would be built in Germany. "Around one-fifth of total rare earths funding is currently being used to manufacture the high-performance magnets, especially in small drives such as hard drives or optical drives in consumer electronics." Already, almost the entire promotion of the rare-earth element Dysprosium for the production of magnets used. The prices for dysprosium have increased from 150 US-Dollar per kilogram in the year 2009 to 660-Dollar in the year 2013. And the need will continue to grow.

The metal trader Gunther Maassen holds a piece of bismuth in his hand. Rare earths hit the headlines in 2011 because the main supplier, China, had tightened export restrictions. The industry feared supply shortages.

But such industrial engines are still not separately collected and disposed of at the end of their lives, complain the authors of the study. "The permanent magnets end up in steel or copper scrap after 30 years at the latest, or are even disposed of with household waste. This means that the industry in Germany is already losing around 35 to 40 tonnes of neodymium-iron-boron magnets - trend for the years 2025 / 2030 strongly rising. "

Öko-Institut recommends setting up the recycling system up to 2030

According to the Öko-Institut, however, there is still no system in sight that would ensure the effective recycling of this magnetic scrap into a circular economy. For this purpose, first a sales market must be built so that the recycling of magnetic scrap is worthwhile. Therefore, the early establishment of a collection and return system would be of strategic importance, since corresponding approaches would have a positive effect on investment decisions in the field of magnetic recycling.

Such a collection system, ideally designed across the EU, could also be built by industry. "The latest 2030 tons of neodymium magnets have to be disposed of by 100 by the time the magnetic waste collection, separation and recycling infrastructure is up and running", demands Matthias Buchert, who led the study at the Öko-Institut.

Source: http://www.ingenieur.de/Themen/Rohstoffe/Oeko-Institut- sucht-Recyclingsystem-fuer-Seltene-Erden