Part 2

switch to part 1 switch to part 3

2 The origin of the crisis

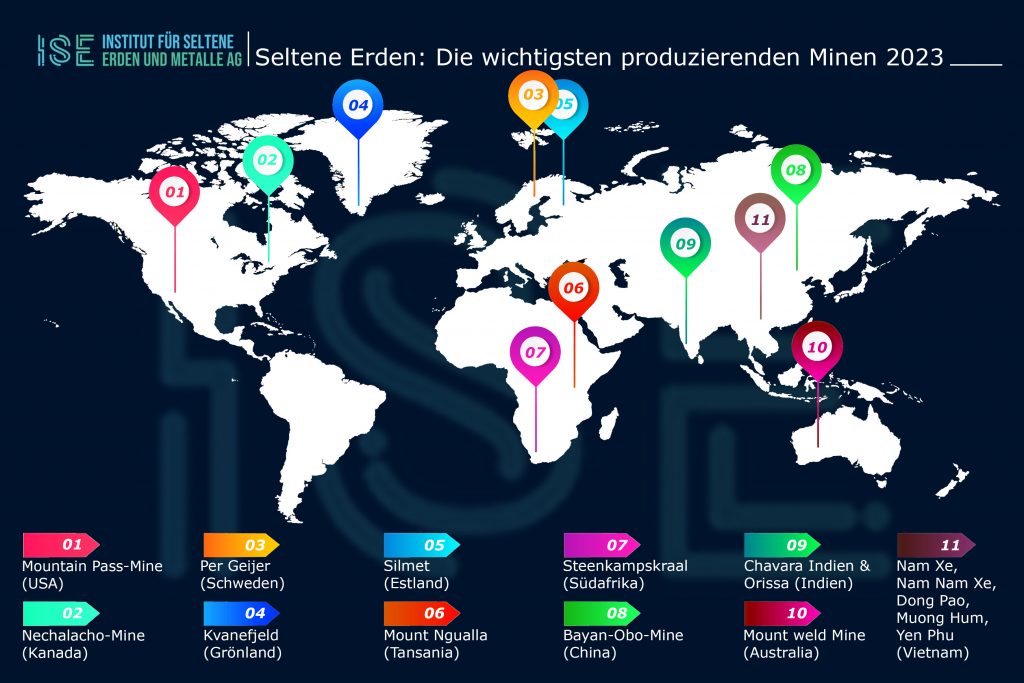

Actually, it is strange that a market that currently only sells around 125 tons of material per year worldwide receives so much media and political attention. The cause of this development lies in the fact that 000% of world production of these critical metals comes from a single country that has continuously and in some cases drastically reduced its export quotas in recent years - China (Fig. 97).

There are two important reasons for this: Firstly, China itself needs more and more of these rare earths to secure its own growth (currently about 70% of total SE production), and secondly, this restrictive export policy is intended to bring Western high-tech production facilities into their own country be relocated. Since it is only logical that the call for a way out and alternatives such as recycling is getting louder.

In fact, the US was until the beginning of 1980er main producer of rare earths. However, due to low Chinese production costs and environmental problems, most mining companies outside of China have stopped production in recent years. Molycorp (USA) and Lynas (Australia) will start mining light rare earths over the next 24 months, easing the supply side of light rare earths.

3 Strategic Alliances and Supply Contracts

The risks associated with reliance on a single provider have since roused all Western markets, politicians and governments. The rare earth business has become a critical bottleneck for the survival and growth of many industries due to the lack of security of supply. A circumstance that can also be seen in the price index for SE oxides and metals, which has exploded in the last two years (Fig. 4).

With the prospect of the impending supply crisis with rare earths large industrial enterprises and governments set up special Task Forces, which are to form strategic alliances with old and possible new SE producers and suppliers. The Federal Chancellor's trip to Mongolia from last October, where billion dollar raw material supply contracts (including rare earths) were signed, or the visit of the Kazakh President to 2012 in Berlin in February is a clear proof of how serious the critical supply situation is also at the highest political level. But here too, only the supply of light rare earths is negotiated. The problem of the future is the supply shortage of heavy rare earths. Even if China succeeds in promoting heavy rare earths, there is the problem of separation. So far, only the Chinese have the technological know-how for this separation process. However, a smaller US corporation from the Rare Earth realm recently announced that agreements have been reached to build a Separation Plant for Heavy Rare Earths with the Chinese. This would mean a small revolution in this market, as other companies that can mine heavy rare earths would also have a partner outside of China who could carry out the separation.

4 The race for victory in the rare earth business

Currently we are counting on 220 companies arguing about a piece of the relatively small SE cake. In the next 3 years, therefore, a consolidation is expected, which will mean the end for many of today's SE projects. But who will ultimately be among the winners in the race for billions in this hotly contested business?

Rare earth projects are very costly at all levels, from exploration to processing. However, there are many factors responsible for success that are not as easy to obtain as capital, talent and experience. There are only a handful of experts in the world who are capable of producing rare earth industrial grade, high purity end products to the highest standards. Exploration and mining are the relatively simple part of the task. They represent only 10-15% of the entire value chain. The SE business has always been more in the field of specialty chemicals than in mining. Therefore, the winners in this race will be primarily those companies that have access to the know-how of the processing and thus are able to develop the value chain in the direction of high quality end products.