Waste heat recovery can lead to clean energy generation at mining sites.

The optimization of the efficiency of diesel gensets arouses the interest of the miners, as a new report from THEnergy shows.

The approach is based on conventional steam turbine technology, but advances have allowed it to be used on a smaller scale.

The principle behind it is to solve the question that diesel engines can only convert 40% of fuel energy into electricity while the rest are not being used. Waste heat recovery can reduce diesel consumption by around 7%.

According to THEnergy, the process has already proven itself in applications such as the heat recovery of biogas engines, the combustion of biomass, industrial waste heat and geothermal energy.

"Use of waste heat is the low hanging fruit in the diesel reduction game," said Thomas Hillig, managing director of the consulting company, in a media statement. “Renewable energies have recently opened the door to new approaches because they have increased the acceptance of more capital-intensive solutions in mining”.

Hilling believes that heat recovery can go hand in hand with approaches to reducing diesel fuel from renewable sources.

“At a time when cost optimization and carbon reduction are gaining in importance, the question is not which of the two solutions should be chosen. The answer is to combine both solutions, ”said the expert.

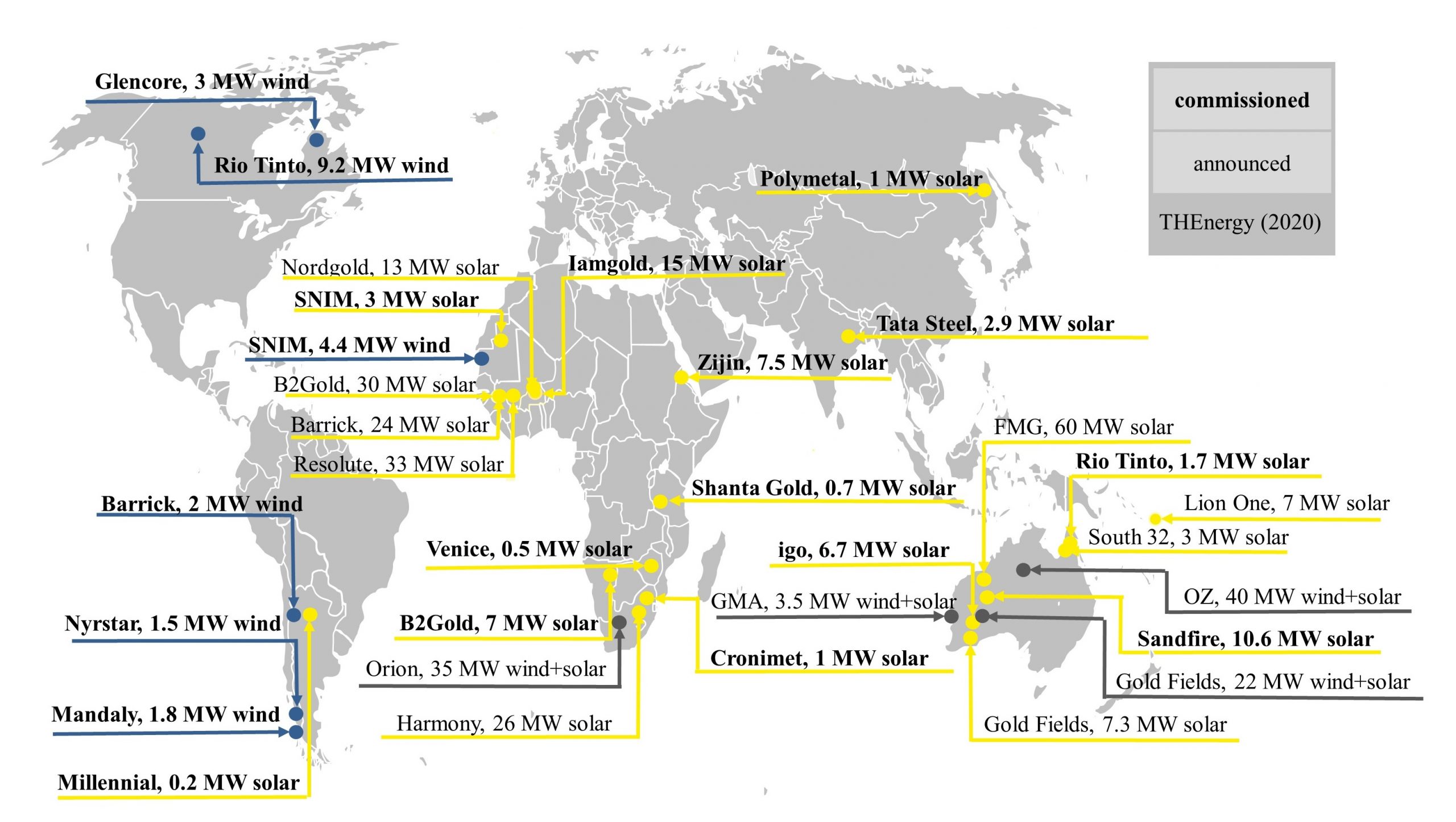

Newly designed and updated version of the world map "Decentralized Renewable Energy in Mining" - (c) THEnergy

THEnergy's document explains that the heat recovery solution works by connecting two standard 20-foot shipping containers to the exhaust ports of diesel gensets. What happens next is that the E-Box generates electricity from the waste heat. The electricity is fed into the local grid so that diesel generators do not have to generate this electricity and then consume less fuel.

Since the E-Box converts the waste heat, it is a zero-carbon technology that drives the drive for cleaner mining. A single electronic box saves 300.000 liters of diesel per year. This roughly corresponds to the output of a 0,7 MW solar power plant in a rather sunny region. The annual CO2 reduction is 800 tons per electronic box.

"In the fast-growing market of renewable energy solutions for remote mines, increasing the efficiency of gensets can create competitive advantages for mining companies and utilities by pulling all the cost-effective diesel reduction levers from local power plants," said Henning von Barsewisch, CEO of Triogen, a provider of distributed power generation equipment. which is derived from the steam turbine process.

Henning explained that the E-Box solution has been successfully tested for mining applications and is now being used in various remote locations of the leading mining companies.

Press release: Text and pictures by THEnergy / Translation ISE - January 2020