A young US company has developed a process to recover rare earth elements from electronic waste. The futurezone has asked.

With his start-up Reecycle (Ree stands for Rare Earth Elements, note), the 25-year-old US entrepreneur Casey McNeil offers a process that allows valuable rare earths to be recovered from electronic waste and at a profit. “We have an organic solvent that enables the recovery of rare earths in the form of metal-organic frameworks. As part of the recycling process, we can selectively reject certain elements, ”McNeil told futurezone. According to McNeil, the solvent is slightly toxic and has a pH value of 6, but can be neutralized to such an extent that no environmental damage is to be feared. This is important because the mix currently has to be changed after a few cycles.

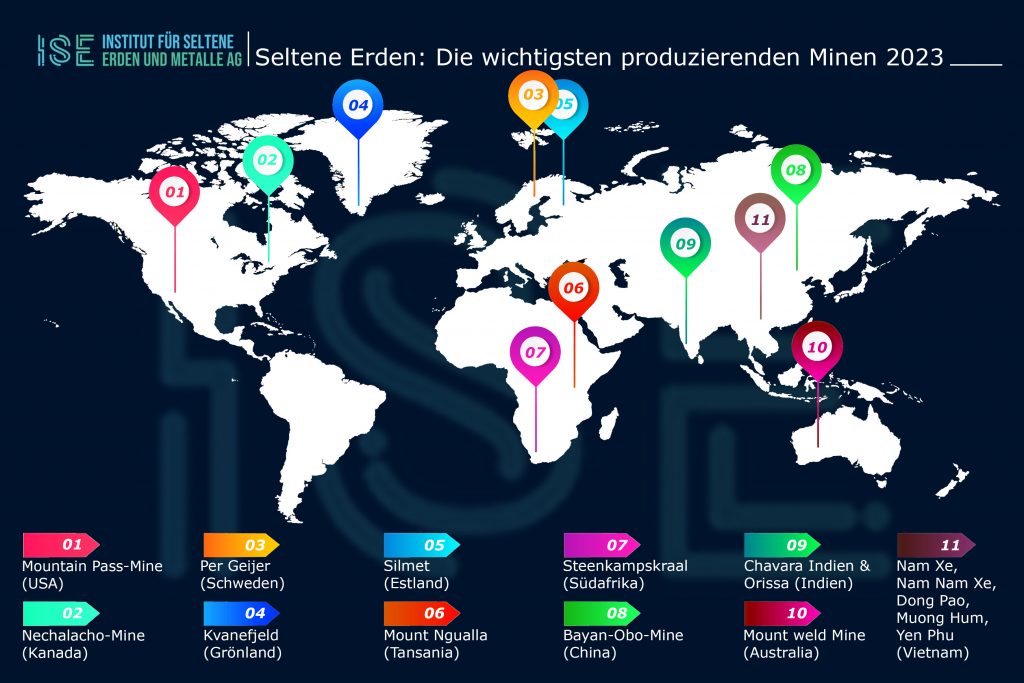

Nevertheless, the environment benefits from the fact that mining, transport and disposal of the rare earths have caused far greater damage so far. The coveted materials, which contrary to their name are not rare, but difficult to break down, are indispensable for many electronic and chemical applications, such as lasers, lighting fixtures, screens, fuel cells, batteries, electromagnets, electric motors or fiber optic cables.

Unique technology

The patents for the procedure have already been requested by Reecycle. There is no comparable technology anywhere else, according to McNeil. Currently, Reecycle specializes in the elements of neodymium and dysprosium, the two most profitable rare earths. Neodymium and dysprosium, for example, play a major role in high-performance magnets such as those used in medicine or in the particle accelerator at CERN in Geneva. "We could use our 15 technique to reclaim the 17 precious rare earths. Five of them are on the list of critical raw materials, such as Europium, Yttrium and Therbium. Right now we specialize in the two most important things, "says McNeil. Reecycle has already started operations in one plant, with additional sites in the US expected to follow for the next three years. "We are in the pilot phase, together with large corporations, which help us to procure the materials, ie the electronic waste," says the young entrepreneur.

In the longer term, a recycling chain should also be set up in Europe, but at the earliest in three to five years. "It's easier in the US because recycling efforts are not as advanced as in Europe," McNeil explains. In three years, 100 to 150 tonnes of neodymium and dysprosium will be recovered from waste in the US. Although this is a small volume, but should still count. "With China controlling almost all of the current deposits of Slender earth and increasing demand, new sources need to be developed. However, building mines outside of China is extremely expensive and takes a long time, "says McNeil. Alternative technologies, such as winning the elements of underwater resources or the space, are currently only desired dreams.

"We already have many prospects with whom we negotiate. They want to integrate our process into their works. There is also interest from China. Although there are large deposits there, but demand is also growing strongly, "says McNeil. In addition, in order to promote small amounts of the elements must be reduced with great effort worthless material. "We've seen 2010 scon a collapse of the rare earth element market and several price rises, so the interest should remain high," says McNeil. Other rare earths could soon be included in Reece's offer as demand and profitability continue to rise.

Source: www.futurezone.at